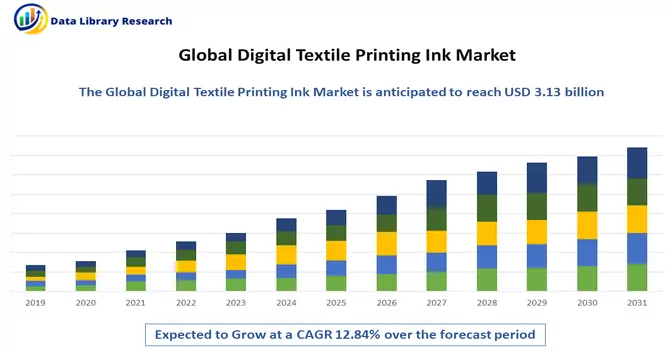

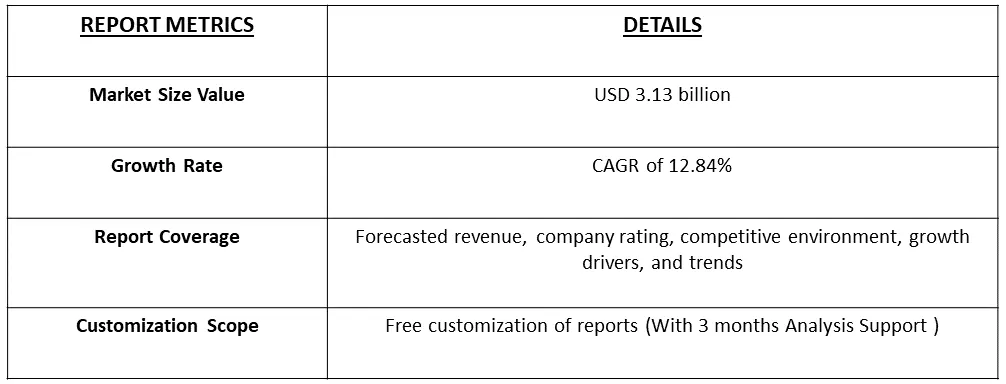

The Global Digital Textile Printing market size is expected to grow from USD 3.13 billion in the previous year to USD 5.72 billion in the next five years, registering a CAGR of 12.84% during the forecast period, 2023-2031.

Get Complete Analysis Of The Report - Download Free Sample PDF

Digital textile printing ink is a specialized formulation tailored for the inkjet technology employed in the digital printing of textiles. Unlike conventional methods like screen or rotary printing, digital textile printing relies on inkjet printers that eject minuscule droplets of ink directly onto fabric surfaces. These inks are meticulously crafted to ensure compatibility with the specific demands of inkjet technology, offering vibrant and accurate colors. The formulations prioritize durability, resisting fading or bleeding during washing, and are designed to adhere to fabric fibers securely. To accommodate the flexibility and stretch inherent in textiles, the inks are engineered to be pliable, allowing printed designs to move with the fabric without cracking or peeling.

The Digital Textile Printing Ink Market is experiencing robust growth driven by the surge in demand for customized textiles and advancements in inkjet printing technology. Sustainability concerns are promoting the adoption of eco-friendly inks, while the cost-effectiveness of short-run production appeals to small and medium-sized enterprises. The expanding applications of digital textile printing, ranging from garments to technical textiles, contribute to market expansion. Fashion and textile industry growth, coupled with the global shift towards e-commerce, further boosts the market. Government initiatives supporting sustainable practices and ongoing technological innovations in ink formulations are additional factors fueling the market's upward trajectory. Overall, the market is characterized by its ability to meet evolving consumer preferences, reduce production costs, and offer eco-friendly solutions in the dynamic landscape of textile printing.

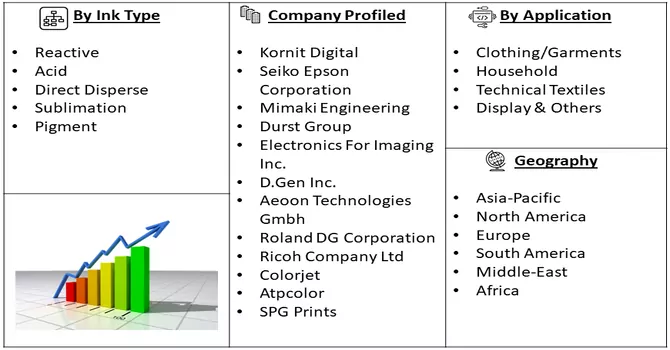

Market Segmentation: The Global Digital Textile Printing Market is segmented by printing method (roll-to-roll printing, direct garment printing), type (sublimation, pigment, and reactive), and Geography (North America, Asia-Pacific, Europe, South America, Middle East, and Africa). The market size and demand forecasts for the pump market in revenue (USD billion) for all the above segments.

For Detailed Market Segmentation - Download Free Sample PDF

The Direct-to-Garment (DTG) printing technique has garnered significant attention, notably within the apparel industry. This method has gained prominence for its capability to facilitate on-demand printing, enabling the customization of designs directly onto completed garments. This trend signifies a transformative shift in the garment manufacturing process, as DTG technology empowers businesses to swiftly respond to individualized customer preferences, reducing production lead times and minimizing waste. The adoption of DTG printing underscores the industry's recognition of the growing demand for personalized apparel and the need for efficient, flexible printing solutions that align with contemporary consumer expectations. An increasing focus is placed on the formulation of high-performance inks tailored to meet precise industry demands, particularly in enhancing key attributes such as superior color fastness, heightened durability, and compatibility across a diverse range of fabrics. This trend underscores the industry's commitment to delivering inks that not only elevate the vibrancy and longevity of printed designs but also exhibit versatility in adhering to different textile materials. The pursuit of high-performance ink formulations reflects a strategic response to the evolving needs of digital textile printing, where the emphasis on quality, longevity, and adaptability plays a pivotal role in meeting the ever-growing expectations of manufacturers and end-users alike. Market Drivers

The increasing focus on sustainable and eco-friendly practices in the textile industry

The market for digital textile printing ink is witnessing significant growth, with a key contributing factor being the growing emphasis on sustainable and environmentally friendly practices within the textile industry. As environmental awareness continues to rise, the textile sector is actively seeking printing solutions that reduce ecological impact. In response to this demand, the digital textile printing ink market has experienced an uptick in formulations designed for sustainability. These environmentally conscious inks aim to minimize chemical usage, conserve water, and adopt eco-friendly compositions, aligning with the industry's commitment to responsible practices. This shift toward sustainability not only reflects broader societal trends favoring eco-conscious choices but also positions digital textile printing as a crucial player driving environmentally friendly innovations in textile manufacturing.

Continuous advancements in digital printing technologies

Continuous advancements in digital printing technologies have been instrumental in shaping the landscape of the digital textile printing ink market. With each innovation, the industry experiences transformative changes that impact print quality, efficiency, and versatility. The evolution of printhead technologies, ink formulations, and color management systems has significantly enhanced the capabilities of digital textile printing.Moreover, the integration of cutting-edge technologies such as artificial intelligence and automation in digital printing processes has further streamlined workflows and increased efficiency. These innovations not only contribute to the overall growth of the digital textile printing ink market but also position it as a dynamic and technologically advanced sector within the broader textile industry.

Marker Restraints:

High Cost of Digital Ink

The growth of the digital textile printing ink market may face challenges attributed to high initial investments and considerations of ink and substrate compatibility. The implementation of digital textile printing technology often requires substantial initial investments in sophisticated printing equipment and infrastructure, which can act as a deterrent for smaller businesses or manufacturers with limited resources. Additionally, the compatibility of inks with various substrates is a critical factor influencing print quality and durability. Ensuring that the ink formulation is suitable for different types of fabrics and materials demands extensive research and development efforts. Issues related to ink-substrate compatibility can lead to suboptimal results, affecting color vibrancy, adhesion, and overall print performance. Addressing these challenges requires continuous technological advancements, research, and industry collaboration to develop cost-effective solutions and make digital textile printing more accessible to a wider range of businesses. Overcoming these hurdles will be essential for unlocking the full potential of the digital textile printing ink market and fostering its sustained growth.

The COVID-19 pandemic has left a discernible impact on the digital textile printing ink market, with disruptions rippling across various facets of the industry. Global supply chains experienced significant disruptions, leading to delays in the production and distribution of digital textile printing inks as a consequence of lockdowns and restrictions. Economic uncertainties and a decline in consumer spending resulted in a slowdown in orders and production for manufacturers in the digital textile printing ink market. However, the pandemic also spurred a noteworthy shift in consumer priorities, with a heightened emphasis on essential goods and a subsequent impact on the types of textiles being produced, influencing the demand for specific digital textile printing inks. Moreover, the surge in online shopping during lockdowns accelerated the adoption of digital printing technologies, prompting businesses to cater to the growing e-commerce market by offering customizable and on-demand textile products. The pandemic heightened awareness of health and safety concerns, driving an increased demand for digital textile printing inks designed for applications such as antimicrobial fabrics. Despite the challenges, the industry showcased resilience and adaptability, fostering innovation in areas such as sustainable and eco-friendly ink formulations to align with evolving consumer preferences. Looking forward, the digital textile printing ink market is poised to navigate through ongoing shifts in supply chain strategies and consumer behavior, emphasizing technological advancements and sustainability as key drivers for future growth.

Segmental Analysis:

Direct Garment Printing Segment is Expected to Witness Significant Growth Over the Forecast Period

Direct Garment Printing and digital textile printing represent crucial segments in the dynamic textile printing industry. Direct-to-garment (DTG) printing has revolutionized apparel customization by enabling the direct application of detailed and vibrant ink onto garments, catering to the demand for personalized and on-demand products. In contrast, digital textile printing utilizes inkjet technology to directly print designs onto various fabrics, extending beyond garments to include home textiles and technical textiles. Both markets are influenced by common trends such as customization, sustainability, and the rise of e-commerce, driving the adoption of these technologies. Challenges include the need for continuous innovation in areas like colorfastness and durability, along with initial investment costs for advanced printing equipment. However, opportunities for growth arise from ongoing technological advancements that enhance efficiency, cost-effectiveness, and expand the range of printable materials. As these technologies evolve, their synergies with customization trends and the growing demand for on-demand production are poised to shape the future of textile printing.

Sublimation Segment is Expected to Witness Significant Growth Over the Forecast Period

Sublimation printing involves the use of specialized inks that, when heated, transform into a gas and permeate the fabric's fibers, resulting in vibrant, permanent, and high-resolution prints. This technique is particularly well-suited for polyester fabrics, as the process relies on the sublimation of inks into the material. Sublimation printing offers advantages such as excellent color reproduction, durability, and the ability to produce intricate designs with a soft feel. It is commonly employed in the production of sportswear, activewear, and promotional items due to its ability to achieve all-over and edge-to-edge printing seamlessly.

Asia Pacific Region is Expected to Witness Significant Growth Over the Forecast Period

The Asia-Pacific region is poised to experience rapid growth in the textile industry, driven by the presence of numerous textile hubs. China and India emerge as the primary contributors to this growth, with Vietnam and Bangladesh also establishing themselves as key players in the textile sector. The expansion of the textile industry in countries like China and India, where labor costs are comparatively low, has been a significant catalyst for market expansion. China, in particular, has been a major textile producer and exporter for several decades, and strategic investments in inventories, including shuttle-less looms and capacity expansions for high-quality fabric production, are expected to further boost the textile and apparel sector. Additionally, the substrate most commonly associated with sublimation ink is polyester cloth. The popularity of polyester has surged in the fashion industry due to its desirable qualities such as wrinkle resistance, abrasion resistance, and cost-effectiveness. Silk, while highly sought after for apparel and home furnishings, faces limitations in its widespread use and market penetration across the region due to its higher costs. Notably, Japan and Gulf nations exhibit a strong demand for silk textiles. Moreover, the ascendancy of digital textile printing and advancements in dye-sublimation technology have brought about a transformative shift in the textile production landscape. This has created new and lucrative market segments and application prospects in the region. The deployment of large format textile printers presents significant opportunities, particularly in soft signage for buildings, store window displays, retail environments, and other points of sale. Concurrently, the burgeoning fashion industry is anticipated to contribute further to market growth in the Asia-Pacific region, positioning the textile sector for continued expansion and innovation.

Get Complete Analysis Of The Report - Download Free Sample PDF

The worldwide digital textile printing market is characterized by fragmentation, driven by intensifying competition fueled by a growing appetite for printed textiles and the allure of stable profitability, enticing new vendors to enter the market. With an escalating demand for sustainable products, major players in the market are strategically focusing on the introduction of innovative offerings and establishing collaborative ventures. This heightened emphasis on sustainability is steering the market towards the launch of eco-friendly and environmentally conscious products. The competition in the industry is further fueled by a concerted effort among market participants to not only meet but also anticipate the evolving needs of consumers in terms of design customization and eco-friendly practices. As a result, the market is witnessing a dynamic landscape with continuous product launches and collaborations aimed at capturing a share in the expanding digital textile printing sector. The strategic focus on sustainable practices and product innovation is expected to remain a key trend as market players vie for a competitive edge in this dynamic and evolving industry. Some of the key market players are:

Recent Development:

1) In April 2023, DuPon Artistri strategically transitioned the production and supply of its Artistri reactive and direct disperse textile inks to Colourtex Industries Private Limited (Colourtex). This move aligns with DuPont's long-term sustainability strategy. Colourtex, known for its manufacturing expertise and extensive product range for textile applications, has now taken the reins in producing and supplying these inks within DuPont's digital portfolio. This collaborative effort is expected to enhance global accessibility and contribute to the advancement of the Digital Textile Printing Ink Market through sustainable practices and strategic partnerships.

2) In 2023, Sun Chemical launched Xennia Amethyst Evo RC, a new generation of reactive printing inks for industrial textile printers. The product was showcased at Stand D302, Hall 5, during ITMA Milan. Building upon the success of the Xennia Amethyst series, Xennia Amethyst Evo represented a high-quality and consistent ink formulation. It was specifically designed to enhance production efficiency, allowing customers to meet demanding volume targets in fashion and home textiles without compromising on quality.

Q1. How big is the Digital Textile Printing Ink Market ?

The Global Digital Textile Printing market size is expected to grow from USD 3.13 billion in the previous year to USD 5.72 billion in the next five years.

Q2. At what CAGR is the Digital Textile Printing Ink market projected to grow within the forecast period?

Digital Textile Printing Ink market is registering a CAGR of 12.84% during the forecast period.

Q3. What are the factors driving the Digital Textile Printing Ink market?

Key factors that are driving the growth include the The increasing focus on sustainable and eco-friendly practices in the textile industry and Continuous advancements in digital printing technologies.

Q4. Who are the key players in Digital Textile Printing Ink market?

Some key players operating in the market include

Data Library Research are conducted by industry experts who offer insight on industry structure, market segmentations technology assessment and competitive landscape (CL), and penetration, as well as on emerging trends. Their analysis is based on primary interviews (~ 80%) and secondary research (~ 20%) as well as years of professional expertise in their respective industries. Adding to this, by analysing historical trends and current market positions, our analysts predict where the market will be headed for the next five years. Furthermore, the varying trends of segment & categories geographically presented are also studied and the estimated based on the primary & secondary research.

In this particular report from the supply side Data Library Research has conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and SOFT) of the companies that active & prominent as well as the midsized organization

FIGURE 1: DLR RESEARH PROCESS

Extensive primary research was conducted to gain a deeper insight of the market and industry performance. The analysis is based on both primary and secondary research as well as years of professional expertise in the respective industries.

In addition to analysing current and historical trends, our analysts predict where the market is headed over the next five years.

It varies by segment for these categories geographically presented in the list of market tables. Speaking about this particular report we have conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and many more) of the major players active in the market.

Secondary ResearchSecondary research was mainly used to collect and identify information useful for the extensive, technical, market-oriented, and Friend’s study of the Global Extra Neutral Alcohol. It was also used to obtain key information about major players, market classification and segmentation according to the industry trends, geographical markets, and developments related to the market and technology perspectives. For this study, analysts have gathered information from various credible sources, such as annual reports, sec filings, journals, white papers, SOFT presentations, and company web sites.

Market Size EstimationBoth, top-down and bottom-up approaches were used to estimate and validate the size of the Global market and to estimate the size of various other dependent submarkets in the overall Extra Neutral Alcohol. The key players in the market were identified through secondary research and their market contributions in the respective geographies were determined through primary and secondary research.

Forecast Model